| 型号 |

Model |

ABD |

| 装盒速度 |

Encasing speed |

x盒/分钟 box/min |

| 封盒方式 |

Box sealing way |

插盒型/粘盒型 |

| 纸盒 |

Box |

质量要求

尺寸范围 |

250-350g/m2

()x()x()mm |

说明书 |

Leaflet |

质量要求

未折叠尺寸范围

折叠范围 |

60-70g/m2

()x()mm

(1-4)/(1-3)折 |

| 压缩空气 |

Compressed air |

工作压力

耗气量 |

>=0.6mpa

20m3/h |

电源

主电机功率 |

Power supply

Motor dimension |

220V/380V 50HZ

xkw |

总功率

外形尺寸 |

Total power

Machine dimension(LxWxH) |

xkw

X x X x Xmm |

| 整机净重 |

Machine weight |

Xkg |

注:用户如有特殊规格,本公司可另行设计制造。

Note: If the user has special specifications, We can design and manufacture according to customer’s special needs.

选配机械:输送带、理料机、发卡机、三位包装机、枕式包装机、贴标机、喷码机、热收缩包装机等。

Optional machinery includes: conveyor belts, material organizing machines, card dispensers, three-dimensional packaging machines, pillow-type packaging machines, label applicators, inkjet coders, and heat shrink packaging machines, etc.

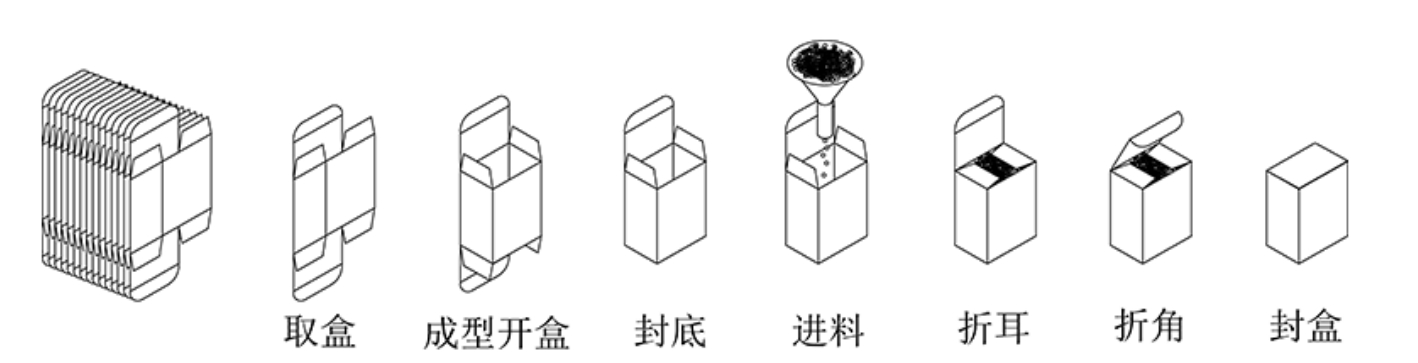

立式装箱机包装作业流程

ABD装盒机是立式装盒机,广泛适用于药品、化妆产品、食品、日用品、医疗器械等需要竖直进入纸盒的产品的装盒包装,能自动完成视觉检测、下托、纸盒吸取成型、物料入盒、纸盒两端封装、缺料剔除及成品输出等过程。

The ABD cartoning machine is a vertical cartoning machine, widely suitable for the packaging of products that need to be vertically inserted into cartons, including pharmaceuticals, cosmetics, food, daily necessities, and medical devices. It can automatically complete processes such as visual inspection, tray feeding, carton suction forming, material loading into the carton, sealing both ends of the carton, missing material rejection, and finished product output.

设备特点

1.模块化设计,可实现适用纸盒尺寸的快速调节。

2.产品垂直入料,能够包裹不规则散装物品。

3.采用PLC可编程控制系统、人机界面显示设备运行状况、故障、报警和成品计数。

4.机器过载自动停机。

5.能在设备前后追加自动送料、自动下托、说明书、打印字码流水号等功能。

6.可根据客户要求选配热熔胶机,采用热熔胶喷胶封盒和机器刷胶封盒。

7.性能稳定、操作简单方便。

1. Allows for quick adjustments to fit different carton sizes.

2. The product is fed vertically, which can package irregular bulk items.

3. Utilizes a programmable PLC control system and a human-machine interface to display the operating status of the equipment, faults, alarms, and finished product counts.

4. The machine will automatically stop if it becomes overloaded.

5. Capabilities to add functions such as automatic feeding, automatic tray insertion, instruction manual insertion, and printing serial numbers before and after the equipment.

6. Can be equipped with a hot melt glue machine according to customer needs, using either hot melt adhesive spraying or machine-applied glue for carton sealing.

7. Ensures stable performance and simple, convenient operation.